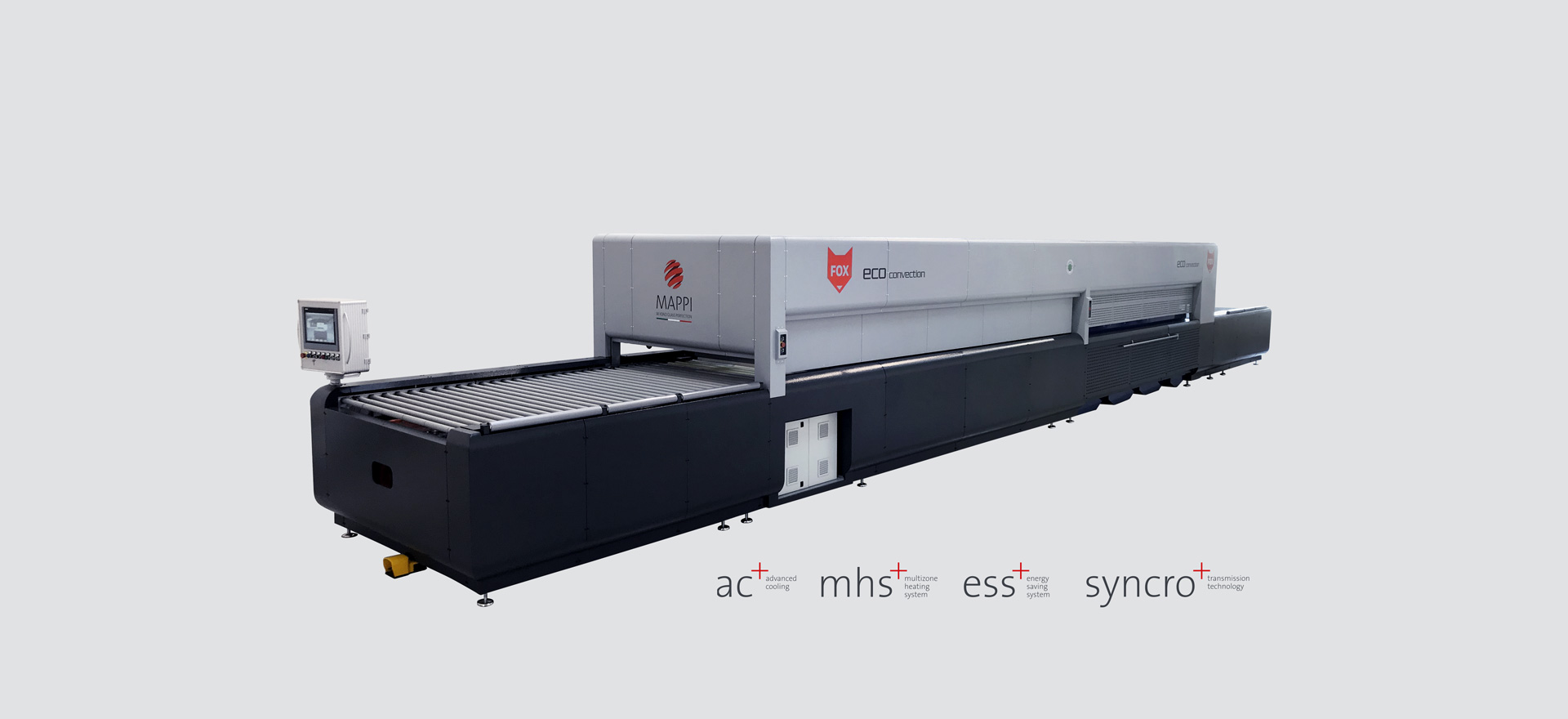

furnaces FOX series

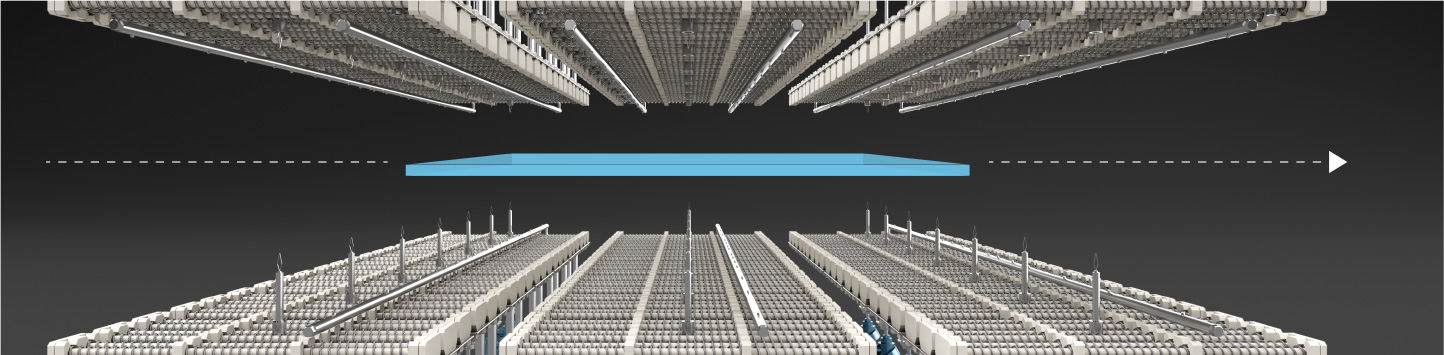

Fox is a series of compact furnaces, with loading dimensions starting from 1050×2300 mm, designed for the needs of medium-small glassworks. Despite its small size, each machine of the Fox series has the most advanced features offered by technology in the sector, and guarantees high quality and cost-effectiveness even in the processing of small series.

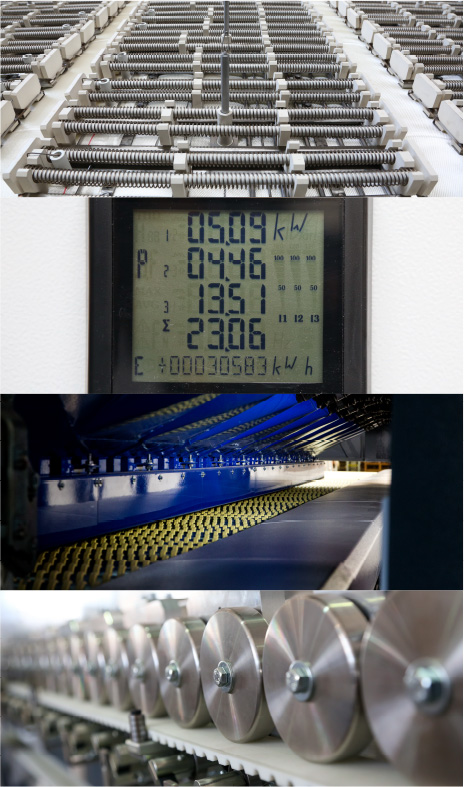

Each oven of the Fox series limits energy consumption through the use of numerous exclusive Mappi solutions such as MHS (Multizone Heating System), AC (Advanced Cooling), ESS (Energy Saving System).

Now, thanks to a solid collaboration with Siemens, Mappi machines are, first in the entire glass industry, recognized as “Powered by Siemens”. This means that they are ready to implement all MindSphere applications, ready to enter the world of industry 4.0. ready to change the way of working in the glass industry, with full integration between the furnace and all production processes, from planning to quality reports. It’s a significant new leap into the future.